Aeroponics Farming : The Project

I recently started working on a high pressure aeroponics (HPA) system and decided to share my journey with you and see how far I can go : from prototype to industrial production.

I find inspiration in projects like The Ocean Cleanup, founded in 2013 by Boyan Slat at the age of 18. I admire how they fight against plastic pollution in oceans by collecting it and recycling it in a smart way.

I grew up in the countryside, in a mountainous region, in short I was surrounded by nature! I like developing tools, web services, making video games... which is quite the opposite when you think about it. What could be better for me than to bring the two worlds together and spend some of my time in trying to solve the next challenges we will face when it comes to food and self-sufficiency? I started working on this HPA system a few months ago hoping to first produce enough for my family and friends, and later why not try to reduce the impact of agriculture on nature while increasing crop yields.

What is aeroponics?

Aeroponics is a form of cultivation where plants grow vertically in the air or in a foggy environment. There is no soil, we use the water to distribute a nutrient solution to the roots.

There are several types of crops with water, the main ones I know are :

- Hydroponics : The plants grow with their roots directly exposed in a liquid nutrient solution. Some people use derivative techniques such as supporting plants on clay pebbles.

- Aquaponics : Same as hydroponics but with a natural nutrient solution from aquaculture (mostly fish). This one may be complex due to aquaculture, but much better in terms of nutrients.

- Aeroponics : It can be practiced in a low or high pressure system. Roots benefit from exposure to air and micro-droplets of water containing the nutrient solution. It is known to be an effective solution in vertical farming with a noticeable improvement in yields.

By growing plants vertically, you gain more space, produce more, and get better yields thanks to a highly oxygenated nutrient solution. A droplet size of less than 50 microns improves the absorption of the nutrient solution by the roots. That's why I use high pressure in my system to get the most productive method while maximizing growing space.

But there are three major drawbacks I see in the HPA system :

- The complexity : Finding the different parts that support high pressure can be really complex, you have to have food grade materials, think about the safety and how to monitor the environment. Any failure in the system can completely damage your plants.

- The cost : Depending on your system setup and location, the price may vary. If, like me, you live in France, you will certainly have to import equipment because it's not produced in this country.

- Pollination : Not only connected to HPA systems but any controlled environments where there are no insects. Although you can remove the pesticides from the equation, man will spend more time doing what the nature normally does. I don't think we have efficient ways to automate this yet, but maybe things will change.

However I think the benefits are worth it, as research from NASA and AgriHouse 1 shows :

- Water consumption reduced by 98% : We use a closed circuit and mist the roots at intervals.

- Pesticide use reduced by 100% : If we are in a controlled environment, we can get rid of the pesticides that kill insects and the natural process of pollination for outdoor crops.

- Fertilizer use reduced by 60%

- Crop yields maximized by 45% to 75%

And finally a paragraph caught my eye in the NASA article, strongly related to what I want to achieve :

By conserving water and eliminating harmful pesticides and fertilizers used in soil, growers are doing their part to protect the Earth. Moreover, the NASA SBIR results demonstrated that this aeroponic technology delivers an 80-percent increase in dry weight biomass per square meter, when compared to hydroponic and soil-based growing techniques.

Agriculture : what's wrong?

Intensive agriculture

It's no secret that we will face major challenges to feed the world's population while maintaining a low impact on the environment. Climate change, wars, pandemics, economic meltdowns and many other factors will have long-lasting impacts on global food security. We need to keep this in mind as motivation to have fault tolerant systems (extreme conditions), efficient solutions and fair pricing. But these are separate and complex topics, in this section I would like to focus on some key figures related to the impacts of intensive agriculture.

Our World in Data published an interesting article 2 where we learn that crop production represents 27% of food emissions with fetilizers and agricultural machinery participating to this. HPA systems can help to reduce the use of fertilizers as we saw previously by 60%. The machinery can also be optimized for vertical farming as everything is more condensed. The author also mentions that land use for crops for human consumption represents 8% of food emissions, which is in my opinion something vertical farming, coupled to the right systems, can improve. Instead of extending the production horizontally we can make good use of height and maximise crop yields.

Grantham Centre - for Sustainable Futures has also published a paper, A sustainable model for intensive agriculture 3, providing some key figures denoting the disaster of this type of farming for the land. We learn that "nearly 33% of the world’s arable land has been lost to erosion or pollution in the last 40 years". We have already consumed our resources and I personnally don't think we are going to improve. We continue to deforest and deplete our soils. I want to quote a part of the paper which summarizes well the situation of our plants and our soils :

Elite modern crops are optimised for a system of high- nutrient artificial inputs and chemical control of pests and diseases; they have consequently lost their natural reliance on microbes to extract complex nutrients from the soil and for defence against natural enemies. Soil is becoming a hydroponic system [...]

We need to adapt our techniques, give the land back to nature and let it regenerate its fauna and flora. Vertical farming will help achieve this goal, and controlled environments will stop pesticide by 100%. However, we will not completely eliminate chemicals and continue to grow naturally weak plants. That's why I believe in using the land in a healthy and smart way, for example by doing permaculture alongside vertical farming which is a temporary solution. Just like the team at The Ocean Cleanup cleaning the oceans of plastic pollution while they know the only solution is a profound change in our habits and the use of plastic.

Another vertical salad farm?

After countless hours of research, I concluded that we have a problem with startups (most of the time) creating vertical farms : they mostly produce salads! Are we going to feed the world with salads? I doubt. I have a feeling that some companies grow under buzzwords and get funding without tackling the real challenges. I know that some plants are easier to grow, especially those that don't involve pollination, or some of them are just incompatible with aero/aqua/hydro-ponic systems. However, I am sure that many varieties of vegetables and fruits can be grown this way and many people have already demonstrated it. I just want to share a list of great gardeners (Youtube channels) for you to learn and see what is possible :

They grow strawberries, blackberries, tomatoes, (hot) peppers, cucumbers, basil, green onions, ... and in extreme weather conditions!

Nutrient pollution

Finally, I want to have this paragraph on nutrient pollution. This will be a problem in all types of agriculture using nutrients. At this time, I'm not sure I can achieve perfect nutrient uptake where the plants absorb 100% of the solution. Lots of tweaking and learning will be needed before running a system without any waste, but I'm optimistic because I will not use soil. I will try to follow this plan to reduce pollution as much as possible :

- Manual tests : during the first tests, errors will be made and I will certainly end up with an unbalanced nutrient solution for my plants. I will try to reuse it as much as possible since the system is a closed water circuit. If that's not possible, I plan to find dirty water disposal companies, but that should be a last resort.

- Iterate : still in a test phase but I will learn and optimize (per plant) more and more and eventually get a balanced nutrient solution that can be fully absorbed.

- Monitor and automate : to deliver the right quantity at the right time. If you're wondering how, I recommend this excellent video of building an automated hydroponic system made by Kyle Gabriel.

High Pressure Aeroponic : System parts

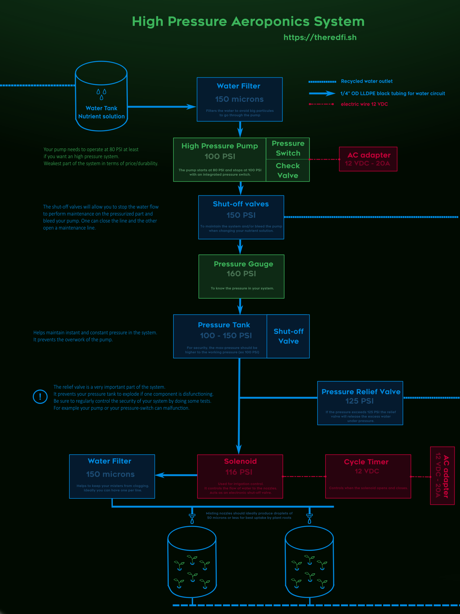

Before setting up my high pressure aeroponic system, I did some research and created a little infographic to help me out. You can consult it with the list below of the main components configured for a working pressure of 100 PSI.

-

Grow chamber : This is where the plants grow vertically without soil and in a foggy environment. It needs enough space to ensure good oxygenation of plant roots. I recommend an insulating thermal barrier made of reflective foil, it will help you to control the temperature and maximize the light between the plants.

-

Black tubing : Generally an open diameter (OD) of 1/4" is recommended (and not less than 1/8" ID). Indeed, you want to build up pressure as quickly as possible and reduce the use of your pump. The water flow is not really important in our system since the nozzles will not allow a large flow per second. However, pressure really matters to get an effective droplet size. The reason you need black tubing is to block light and prevent algae or bacteria growth, which should also help to prevent clogging. Finally, make sure you have a working pressure corresponding to the needs of your system and keep in mind that the temperature influences it.

-

High pressure pump : It delivers the nutrient solution to the system. You need a pump capable of producing a pressure of at least 80 PSI. The higher the better, it will be easier to lower the pressure in your system than to raise it.

-

Pressure switch : It controls the starting of the pump (cut-in at 80 PSI) and its stops (cut-off at 100 PSI). The pump is just there to pressurize the water in the system, so no need to run it continuously.

-

Check valve : Place this after your pump outlet to prevent a backflow in your piping system. It will avoid any damage due to pressure when stopping the pump.

-

Water pressure tank : One of the most important parts of your system to increase the life of your pump. It will pressurize the water with a preset, here at 98 PSI (2 PSI under the pump pressure), so the pump only delivers what is needed. Be sure to choose a pressure tank with a maximum pressure higher than your working pressure so that you are on the safe side. Ask a professional to install the pressure tank and check it regularly.

-

Relief valve : Very important, place it as close to the pressure tank as possible. If your pressure switch fails and the pump continues to pressurize the water, the relief valve will release the water flow and prevent your pressure tank from exploding. In my system I use a 125 PSI relief valve.

-

Presure gauge : To control your line under pressure.

-

Shut-off valves : To close the water circuit and help you purge your installation.

-

Solenoid : Normally closed, when it receives an electrical signal it opens and lets the water flow. Coupled with the recycle timer, this is what helps control the misting cycles.

-

Recycle Timer : Set it to control the solenoid. You can have different cycles for days and nights. I'm going to start with a 5 seconds on, 3 minutes off misting cycle. Then I will iterate to find the best configuration.

-

Nozzles : These are very difficult to find. They should have a working pressure between 80 and 100 PSI (better) and a droplet size of 50 microns or less to deliver the nutrient solution most efficiently. But you will need to make sure your nozzles don't clog easily and this will depend on the material, working pressure, salt in your solution, chemical reactions with the other parts of your system, temperature, ... so many things!

-

Fittings : I recommend John Guest of DmFit fittings for the quality and variety of fittings. Plus, everything is food grade.

The real difficulty will be finding food grade materials for your system and the right fittings for the working pressure. Consult the High Tech Gardener Youtube channel, everything is perfectly explained there!

Next phases

It was important for me to describe the motivation behind this project and to give a quick presentation of the system itself. This is just the surface of the matter, there is so much more to learn!

The next phase will be a bit more fun as I will install the system and test it! As soon as it's finished I will write a new blog post about it.

This will take several iterations, but at some point I plan to automate the system with a Raspberry Pi, sensors, and some programming with Rust. I can't wait to get to this stage!

Footnotes

-

Progressive Plant Growing Has Business Blooming, NASA, Originally published in 2006 ↩

-

Food production is responsible for one-quarter of the world’s greenhouse gas emissions, Hannah Ritchie, November 06 2019 ↩

-

A sustainable model for intensive agriculture , Grantham Centre - for Sustainable Futures, 2015 ↩